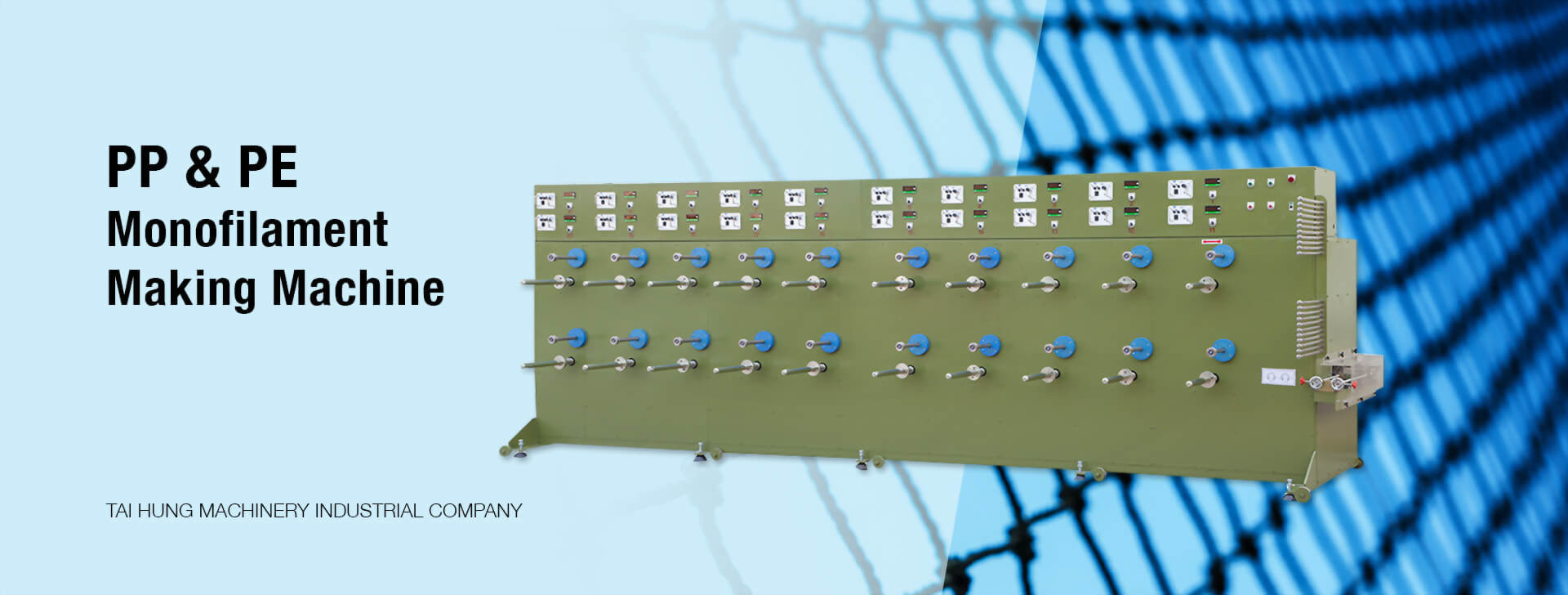

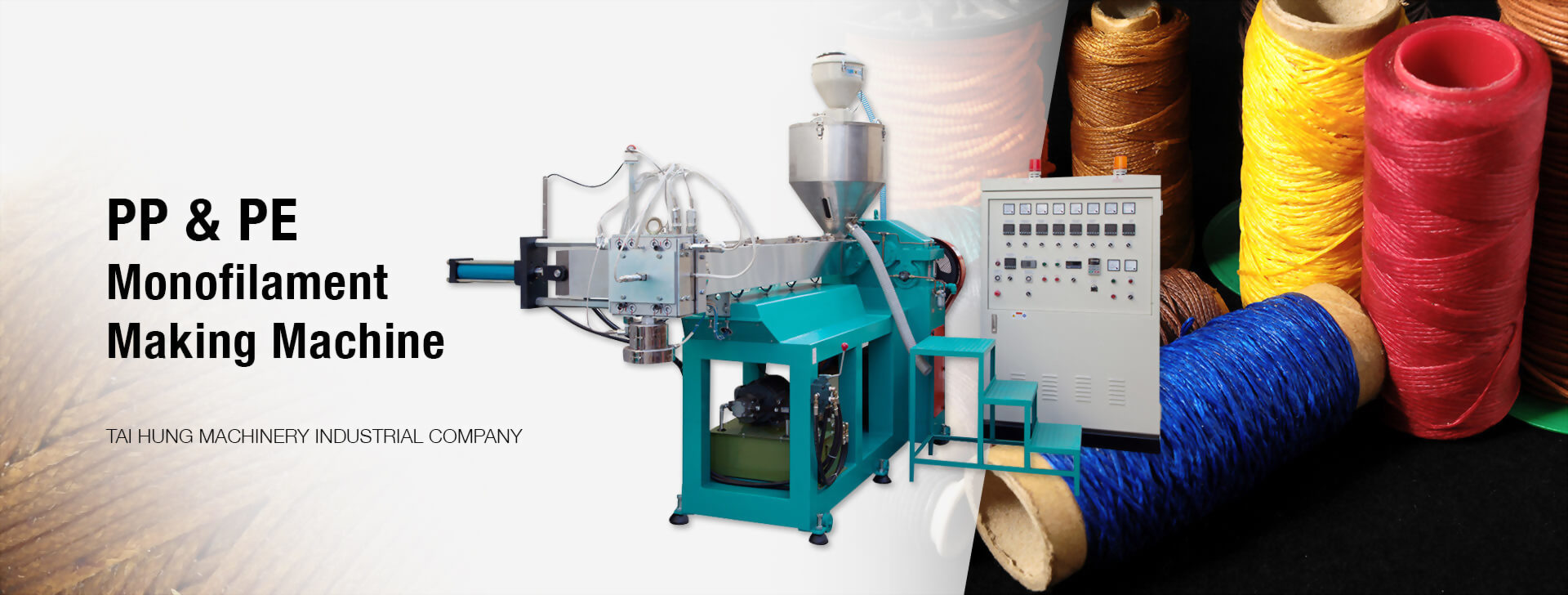

PP/PE monofilament making machine

Model : TH-MM

This yarn making machine is for the purpose to extrude HDPE monofilament and PP monofilament for making mosquito net, screen, sofa covers, fishing net, ropes, fiber reinforced concrete and nets for various use in agriculture.